United Low Retention Digester

United Low Retention Digester

The Anaerobic Treatment of waste water is well established process which has wide range of application. This process is being used by most of the industries and more than 80% of the treatment is being undertaken through UASB type of digester.

However, the anaerobic treatment of waste water with COD values ranging from 2000 to 130000 mg/l needs adequate retention time and area (foot print) . At present the cost of owning land is becoming expensive day by day, this is true for existing or up-coming industries, Hence installation of ETP has been very challenging as the available area may be a constraint.

M/S United Envirotech Pvt.Ltd.(UEPL) has established its name in the UASB process with its consistent performance. The expertise and in-depth knowledge motivated UEPL to innovate so that the treatment becomes even more advanced. The in-house study and developments yielded fruitful results. UEPL has successfully developed a new anaerobic digester. This digester requires very low retention time for treatment and very less area (15 to 20% of the normal UASB digester) for installation.

ULRD at Warna SSKL Maharashtra

ULRD at Satia Industries Ltd. Punjab

Features of the ULRD Process

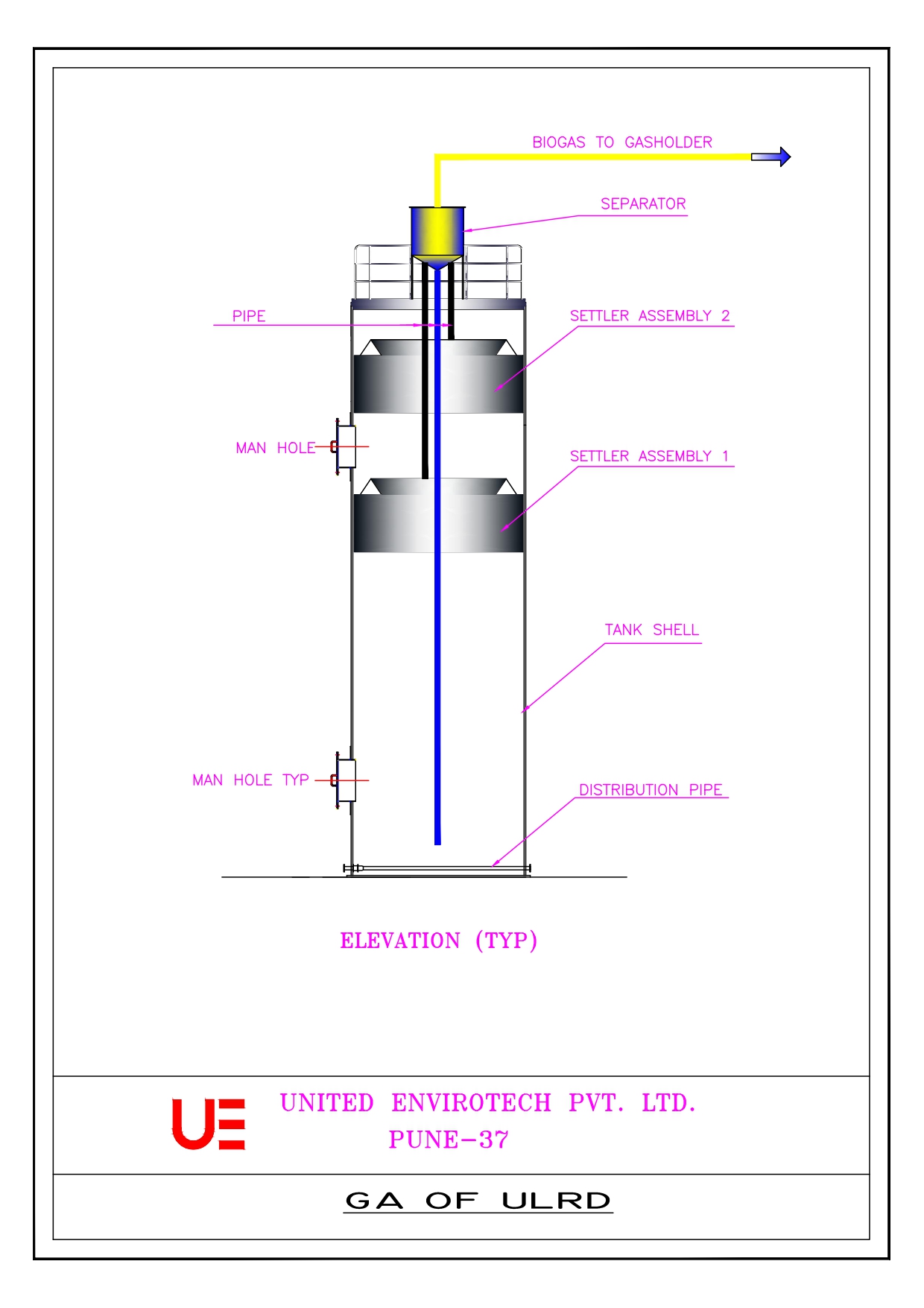

- An effective separation between the Biogas, liquid & sludge is achieved by Gas solid separator in two stages.

- The ULRD height is 20 -25 mtrs, thereby reducing the foot print.

- The unique gas-liquid recycle ensures total anaerobic condition in the system , this avoids scaling and other process issues.

- U-LRD has no moving parts. It requires only one feed pump for supplying the effluent to the bottom of the tank.

- The ULRD requires minimum operating power during treatment.

- The area required is minimum compared to UASB digester.

- The odor emanated during the process will not spread as the digester top is covered.

- Maintenance is minimum.

- The performance of ULRD is at par or better than normal UASB Digester in terms of COD reduction and gas generation.

Biogas Generation in the ULRD System

The Biogas is generated as a by product during the treatment of effluent. COD of the effluent gets reduced during methanogenesis reaction. The Biogas consists following components: (in case of wet wash)

Methane : 63% v/v +/- 5%

CO2 : 32% v/v +/- 5%

H2s : 0.6 % v/v +/- 0.5%

Vapor : 3% v/v +/- 2%

The calorific value of the Biogas is about 5200-5300 kcal / Nm3.

The process industries wherein the U- LRD system will be beneficial are

- Dairy - The effluent COD will be in the range of 1500 – 2000 mg/lit

- Breweries -The effluent COD will be in the range of 3500-4500 mg/lit.

- Paper & Pulp - The effluent COD will be in the range of 3500-4000 mg/lit.

- Sugar - The effluent COD will be in the range of 3400-4000 mg/lit.

- Petrochemical - The effluent COD will be in the range of 6000-7000 mg/lit